Don’t Forget – IR Inspections of Electric Motors

P/PM Programs routinely include highly visible items such as electrical systems, roofs and structures, and HVAC Systems.

P/PM Programs routinely include highly visible items such as electrical systems, roofs and structures, and HVAC Systems.

However, electrical motors tend to be both out-of-sight and out-of-mind until they fail. Infrared thermography can be used as a cost-effective diagnostic tool for detecting problems within electric motor systems. When performing an Infrared Inspection of an electrical motor, the following should be considered:

• With cover removed, inspect electrical connections at the motor junction box. This should be done in conjunction with the regularly scheduled inspection of the facility’s electrical system.

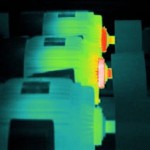

• Inspect motor casing for localized hot spots which may be indicative of short circuits within motor windings. Qualitatively compare individual motors to similar motors under similar load.

• When possible, qualitatively compare inboard and outboard bearings for each motor. If a large Delta T is present, it may be indicative of misalignment or a rotor balance problem. If both bearings are hot, the bearings may be worn or improperly lubricated.

Infrared inspections typically can be performed rapidly and at a fraction of the cost of other types of motor testing. Additionally, infrared can detect evidence of misalignment at lower thresholds than those detectable by vibration analysis and motor current signature analysis.

Jersey Infrared Consultants’ certified infrared thermographers thoroughly understand the theory and operation of electric motors. Contact us to discuss how infrared inspections of your motors can improve your facility’s P/PM.