Steam

Infrasonic™ Steam System Surveys

Many sites produce or buy steam for heating or manufacturing purposes. As essential components of a steam system, steam traps are mechanical devices that can have a direct and substantial impact on your bottom line. Today’s energy costs, combined with an average industry failure rate exceeding 50% of installed traps, could be causing your facility to lose hundreds of thousands of dollars per year!

Utilizing a multi-technology approach, our Infrasonic™ Steam System Surveys are performed by Infraspection Institute Certified Infrared Thermographers® using contact ultrasound detectors and thermal imaging.

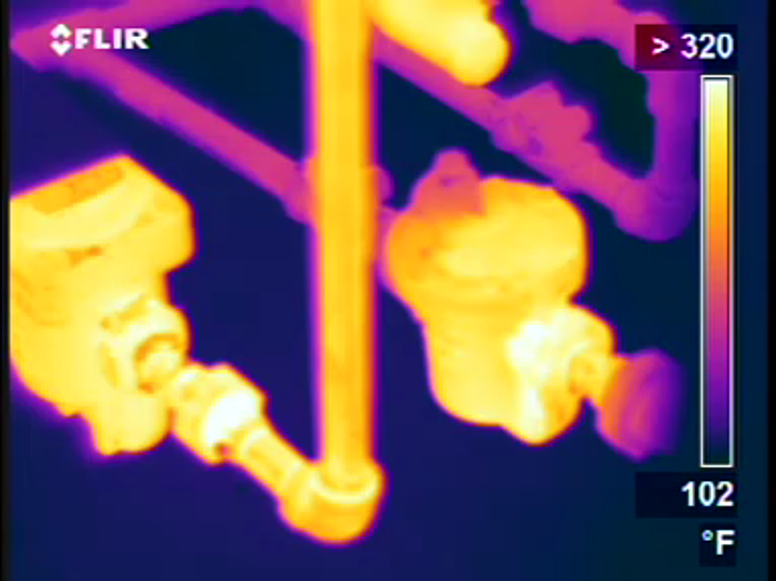

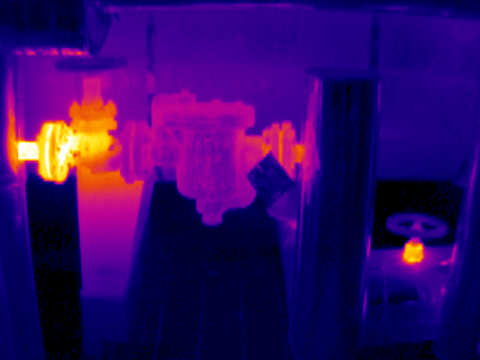

Properly Operating Traps

Failed Steam Trap

Cold Steam Trap

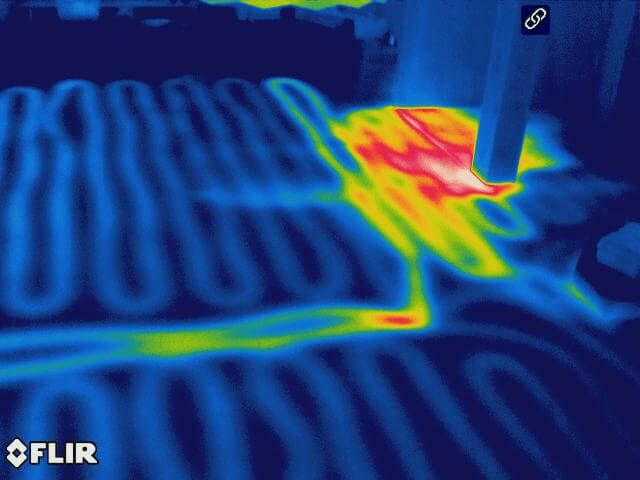

Radiant System Leak

Combined with timely, effective repairs, our Infrasonic™ Steam System Surveys provide you with the information to help eliminate energy waste, reduce your carbon footprint, and increase your bottom line. Locating and repairing a single failed trap can pay for an entire survey.

When performing an Infrasonic™ Steam System Survey, Jersey Infrared Consultants utilize both infrared and contact ultrasound technologies to provide you with a detailed report of the condition of your steam system.

Jersey Infrared Consultants have been providing Infrasonic™ Steam System Surveys since 1984. All work is performed by Infraspection Institute Certified Infrared Thermographers® using state-of-the-art equipmentwearing appropriate PPE, and in compliance with current industry standards.

Applications

-

Preventive/Predictive Maintenance

-

Condition Assessment

-

Condition Monitoring

-

Quality Assurance

-

Forensics

Benefits

-

Non-Contact, Non-Destructive

-

Performed While Under Load

-

Eliminate Energy Waste

-

Provide Documentation for LEED Certification

Contact us to schedule your Infrasonic™ Steam System Survey.

FAQs

Industry statistics put the average failure rate of steam traps at 50%. Combined with record high energy prices the potential loss is staggering. Jersey Infrared Consultants InfraSonic™ Steam System Surveys provide you with the information you need to help eliminate waste and keep your steam system at peak performance.

An InfraSonic™ Steam System Survey combines infrared thermography and contact ultrasonic testing. The result is a comprehensive test which quickly and accurately detects costly, defective steam traps.

The next step is to perform a contact ultrasound test. Properly working traps are generally quiet and cycle at moderate intervals. Traps which are found to be passing steam or cycling too frequently are documented with a thermogram, control photograph, and all pertinent data. This information allows maintenance personnel to investigate the cause and perform corrective measures.

Proper preparation for an upcoming InfraSonic™ Steam System Survey can help keep inspection costs to a minimum and provide better data. Be sure the system is under load; have keys and access codes for all secured areas; and notify tenants or key personnel as appropriate. Have site drawings indicating the location of all traps available. As with any infrared survey, a clear line-of-sight is required and any protective guards or insulation should be removed.

The order in which equipment is surveyed, otherwise known as Routes, should take into account the logistics of moving from location to location and any changes in load demands occurring during the day. If traps do not have an identification tag, plans should be made to attach a tag at the time of the survey.

Standards that apply to InfraSonic™ Steam System Surveys are authored by the ASTM International (ASTM), and Infraspection Institute. Following these standards will help ensure quality results from your InfraSonic™ Steam System Survey. A list of standards followed by Jersey Infrared Consultants can be found on our Standards Page.

Jersey infrared Consultants Infrasonic™ Survey reports are clear, easy-to-understand, and available in hardcopy and/or digital formats. Your report will include the following:

• Thermograph’s Comments will discuss the areas inspected, number of problems identified and special notation of any serious problems.

• Route(s) that provide a detailed list of all equipment surveyed, including location, type of equipment, identification, status at the time of the survey, and notation of problems along with their severity.

• Deficiencies will be documented with a Thermogram, control photograph, and a description that includes the following information:

- Equipment ID and location

- Ambient temperature

- Temperature of the trap, supply or condensate line

- Ultrasonic test results

- Detailed description of the problem