Infrared Windows 101 – The Basics You Need to Know – Presentation

Introduction

Advantages of Infrared Electrical System Surveys

- Locate loose connections, faulty equipment, over/unbalanced loads

- Help identify problems before a failure, allowing a scheduled repair

- Improve reliability and decrease downtime

- Comply with insurance company requirements

- Meet industry specific inspection requirements

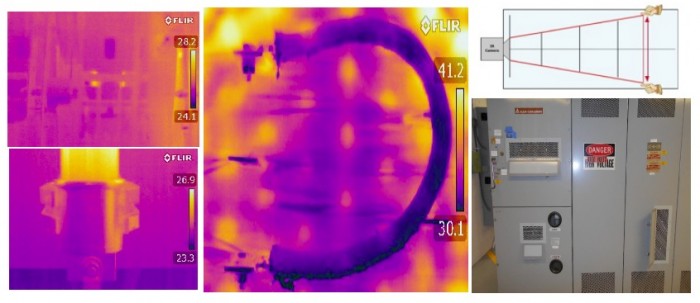

Challenges of an Infrared Survey

- Requires a direct line of sight to the target

- Electrical equipment must be open at the time of the survey

- Time and cost of preparing for the Survey

- Arc Flash requirements must be followed

|

|

Overcoming Challenges of an Infrared Survey

- Use in-house staff to open and close equipment

- Hire an outside contractor to open and close equipment

- Install Infrared Windows

|

|

Window Types

Ports or Fish Eyes

- Consists of a metal or plastic frame

- Has a single, small diameter opening (< 0.5 inches)

- Usually require the use of special wide angle or ‘fisheye’ lenses

- Thermal imager must be designed to accept such lenses

Grills

- Similar to ports – Larger diameter than ports

- Contain a metal plate – Multiple small diameter openings or do not have a solid barrier or pane

- Thermal image may show the metal plate

- Electrical components visible through the openings

Infrared or IR Window

- Specially engineered optic – Designed to permit infrared inspections of electrical components or crystal or polymer material that is infrared transmissive

- Metal or plastic frame to support the optic pane

- May or may not have a grill in place

- Protective covering when they are not in use

- Various shapes and sizes are possible

IR Window Components

- Backing Ring or Plate

- Lens or Optical Plane

- Front Ring or Plate

- Cover

- Optional – IR Label & Equipment ID

Crystal Panes

- Original material used for Infrared Windows

- Germanium, Zinc Selenide, Calcium Fluoride and Sapphire

- CorDEX, FLIR, Fluke and IRISS

| Crystal Advantages | Crystal Limitations | |

| Ideal for high ambient temperatures Limited to 4″ diameter | Limited to 4″ diameter | |

| Withstands extreme environments | Round shape only | |

| Allows visual inspections | Not impact resistant | |

| Compatible with all IR Imagers | Usually more expensive than polymer |

Polymer Panes

- In use since the late 1990’s

- Opaque or clear

- With or without reinforcement

- Exiscan, IRISS

| Polymer Advantages | Ploymer Limitations | |

| Ideal for industrial environments | Not suitable for high temperature environments (over 200°C) | |

| Stable, consistent transmissivity | An expert should be consulted before ordering custom sizes or shapes | |

| Compatible with all IR Imagers | Not all are clear | |

| Impact resistant | ||

| Size and shape options available | ||

| Less expensive than crystal |

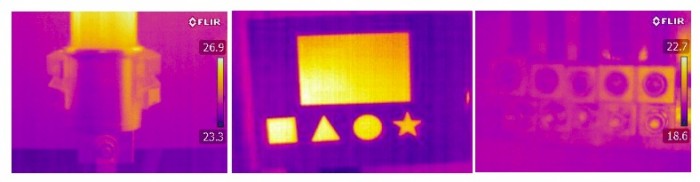

How IR Windows Work

- Optic lens are infrared transmissive

- Data collection point installed in the metal

- Infrared imager lens is placed directly on the window

- Thermal data is recorded same as with equipment open

Advantages

Data Management

-

- Same target, location, distance and angle

- Consistent trendable data in any PdM process

- Use IR Labels for standardization

Risk Management

-

-

-

- Eliminate risk where possible

- No longer required to open and close panels

-

-

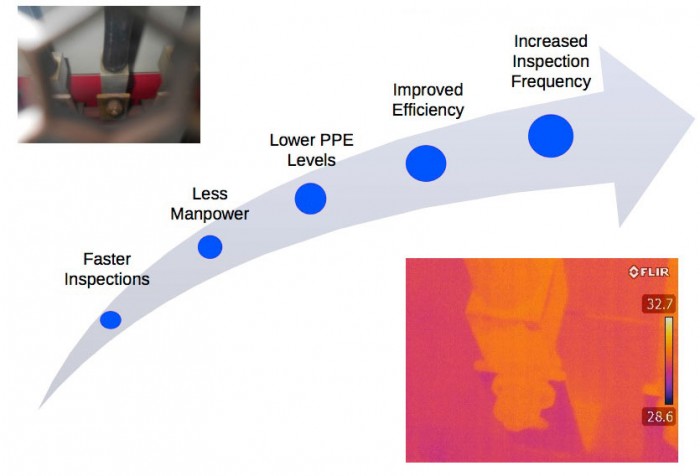

Safety

-

-

-

- Survey energized electrical equipment

- No removal of the panels

- Reduces the risk of an arc flash incident

-

-

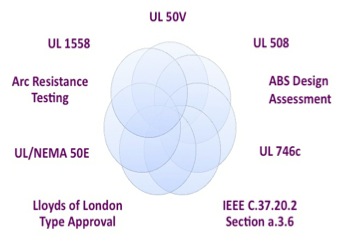

Standards Compliant

-

-

-

- Equipment remains enclosed and guarded condition

- Reduces potential electrical hazard during inspection

- Survey equipment not previously accessible

-

-

Selecting IR Windows

Facts to Consider

-

-

-

- Available Field-of-View

- Camera lens compatibility

- Environment

- Need for visual or ultrasonic

-

-

Components to be inspected

Where to Install IR Windows

Considerations

- Frequency of the equipment to be inspected

- Complexity of opening the panels

- Arc flash precautions

- Facility safety requirements

Common Equipment

- Dry-type Transformers

- MCC

- Distribution Panels

- Switchgear Cabinets

- High & Medium Circuit Breakers

- Control Cabinets

- RestrictedAreas

Qualified, trained personnel

- Must understand proper window placement

- May opt to work with an experienced thermographer

Identify all targets

- Fuses, breakers

- Cable and bus connections

- Any mechanically fastened connection

IR ID labels ensure repeatable data collection

How to Pay for IR Windows

| Number electricians required to open/close | X | Number of days to perform the Survey | = | Number of Electrician Man Days |

| Number of Electrician Man Days | X | Cost per electrician per day | = | Total Cost of Electricians |

| Number of days to perform the Survey | X | Cost of Thermographer per day | = | Thermographer Cost |

| Total Cost of Electricians | X | Thermographer Cost | = | Cost of Traditional Infrared Survey |

One Time Costs

| Number electricians required to open/close | X | Number of days to perform the Survey | = | Number of Electrician Man Days |

| Purchase of IR Windows | X | Cost of Installation | = | Permanent Solution |

| Number of Electrician Man Days | X | Cost per electrician per day | = | Total Cost of Electricians |

Cost of Future Infrared Surveys

| Number of days to perform the survey | X | Cost of Thermographer per day | = | Thermographer Cost |

How to Start an IR Window Program

When purchasing IR Windows

- Consider bulk purchases

- Possible discounts

- Prevent any delays during installation

- Possibly allow additional windows to be installed

Possible Sources of Funds

- Money left in your budget

- Capital Improvement

- Safety Budget

- Insurance Reductions

- Reliability or Cost Avoidance

- Regulation Compliance

List of all equipment that should have IR Windows

- Prioritize each piece of equipment

Make inventory of all needed IR Windows

-

- Type of window, location, installation schedule

Plan the installation of the windows

- Start with highest priority

- Availability of equipment

- Frequency of inspections

- Safety hazardous risks