Company News

Infrared Training Continuing Education

Infrared Training Continuing Education

We have all heard the phrase, “A chain is only as strong as its weakest link.” When it comes to thermography, the weakest link is frequently not the test equipment but rather the thermographer. While thermography is a science, it is also a craft requiring a skilled operator for both conducting the inspection and interpreting the data obtained.

We have all heard the phrase, “A chain is only as strong as its weakest link.” When it comes to thermography, the weakest link is frequently not the test equipment but rather the thermographer. While thermography is a science, it is also a craft requiring a skilled operator for both conducting the inspection and interpreting the data obtained.

Infrared Applications Beyond Electrical Inspections

In the commercial and industrial workplace, infrared thermography is commonly used to inspect electrical systems and flat roofs. However, there are several other areas nhere use of an Infrared Survey can provide valuable information.

What should an Infrared Survey report include?

At the conclusion of an Infrared Survey, the findings should be documented in a clear, easy-to-understand report, in a written format as well as electronic.

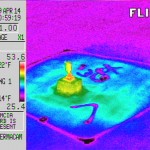

Infrared Thermography and Photovoltaic Systems

An Infrared Photovoltaic System Survey can detect and document serious defects within operating solar panels that are undetectable by any other means. Performed regularly, infrared inspections of Photovoltaic Systems can help to reduce maintenance costs and ensure system efficiency.

When functioning properly, PV panels should exhibit the uniform thermal patterns. Thermal anomalies may indicate a potential problem involving an individual solar panel or its cells. Typical problems detected during an Infrared Photovoltaic System Survey include:

Jersey Infrared Consultants Purchases New Infrared Imager

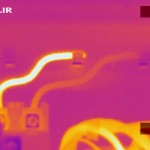

Jersey Infrared Consultants is excited to announce the purchase of our newest Infrared Imager – a FLIR GF309. Although primarily designed for use in Petrochemical applications, the high resolution, expanded temperature range and short wavelength features make this an ideal IR imager for electrical, roof and data center inspections.

Jersey Infrared Consultants is excited to announce the purchase of our newest Infrared Imager – a FLIR GF309. Although primarily designed for use in Petrochemical applications, the high resolution, expanded temperature range and short wavelength features make this an ideal IR imager for electrical, roof and data center inspections.

Determining if a Roof is a Candidate for an IR Survey?

Infrared Flat Roof Moisture Surveys can usually be performed on commercial flat or low-slope roof systems that are composed of a roof membrane over and in direct contact with insulation. The presence of insulation is necessary to provide a material to retain the moisture as well as to absorb solar energy. The membrane may be built-up or single-ply, smooth or gravel surfaced, or have a coating of any color.

IR Windows Eliminate Panel Cover Removal

Because infrared imagers cannot ‘see’ through solid objects, accurate infrared inspections of electrical switchgear require the removal of panel covers to provide a direct line-of sight to subject components. Often, panel cover removal/replacement is the most time-consuming aspect of an infrared inspection. One alternative is the installation of IR switchgear windows.

Because infrared imagers cannot ‘see’ through solid objects, accurate infrared inspections of electrical switchgear require the removal of panel covers to provide a direct line-of sight to subject components. Often, panel cover removal/replacement is the most time-consuming aspect of an infrared inspection. One alternative is the installation of IR switchgear windows.

Moisture Around Roof Pitch Pockets

Most roofs have pipes, vents or other penetrations that require special details to prevent infiltration of moisture. A roof pitch pocket is a sheet metal box with a flange on the bottom and is designed to surround roof penetrations. The flange is secured under the roof system to provide a water-tight seal.

Standards for Infrared Inspections of Electrical Systems

Performed properly, infrared inspections are a valuable tool for preventive/predictive maintenance of electrical systems. Current industry standards cover inspection procedures, certification of personnel, equipment selection and use, and safety. Presently, standards that apply to infrared inspections of electrical systems are published by: