FAQs about Infrared Photovoltaic System Surveys

– What are the basics of Photovoltaics (PV)?

– How does an Infrared Photvoltaic System Survey work?

– Should Surveys be performed from the ground or air?

– What conditions are required for an Infrared Photovoltaic Survey?

– What safety requirements apply to Infrared Photovoltaic System Surveys?

– What standards apply to Infrared Photovoltaic Surveys?

– What should your report include?

– Why should you use Jersey Infrared Consultants?

What are the basics of Photovoltaics (PV)?

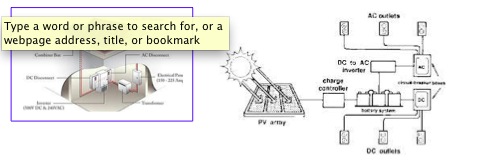

Photovoltaic system (PV) is a method of converting solar irradiance or solar power (the Sun) into direct current (DC) electricity. The DC power can be used directly or converted to AC power for standard applications.

A photovoltaic system for residential, commercial, or industrial energy supply normally starts with a photovoltaic array. This array consists of multiple solar panels designed and placed to collect the maximum amount of solar energy. Collected energy can be stored in a battery system. If the end use requires AC power, a DC to AC inverter is used.

The number of panels in the system determines the total DC watts capable of being generated by the solar array; however, the inverter ultimately governs the amount of AC watts that can be distributed for consumption.

How does an Infrared Photovoltaic System Survey work?

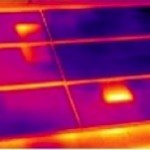

Infrared thermography is a form of non-contact, non-destructive testing used to detect and document thermal patterns of installed photovoltaic panels. Our high-resolution infrared imaging radiometers detect infrared energy emitted from an object and converts it into an image which is displayed on a monitor screen.

When inspected during the correct site conditions, properly operating solar panels should be uniform in temperature, with no pronounced hot spots. Thermal anomalies, or hot spots, caused by defective cells within panels are usually due to cell failure, faulty wiring within the panel, partial shaded, and/or dirt or debris on the panels. Left unresolved, defective cells can compromise panel efficiency or lead to premature panel failure.

When a component or panel with an unusual thermal pattern is located, the thermal image and control photograph will be recorded. The thermogram, control photograph and exception information are compiled into a report that is available in hardcopy and digital formats.

Should the Survey be performed from the ground, an elevation or air?

When deciding whether to perform an Infrared Photovoltaic System Survey from the ground, an elevated surface or by aircraft, many factors should be considered.

Ground based surveys:

- Panels may be inspected from either top side

- If accessible, the underside of subject panels can also be inspected

- The thermal imager may be hand carried or mounted on a cart

- Thermograms are taken for exceptions or panels of interest

- Caution must be taken while walking in close proximity to solar panels.

- Small areas of thermal anomalies are detectable

- No flight pattern restrictions

- Cost is usually significantly less than aerial

Elevated vantage point surveys:

- The thermal imager may be hand carried or mounted on a cart

- Inspect a larger solar field in a shorter time as compared to ground based

- Smaller areas of thermal anomalies are detectable than by aerial inspections

- No flight pattern restrictions

- Cost is usually significantly less than aerial

Aerial surveys:

- Survey very large or remote areas in a shorter period of time

- Look at areas that may not be accessible by foot due to site or safety issues

- Collect information to compare overall conditions of multiple panels

- Thermal imagery is typically obtained for subject solar panels and later analyzed for the

presence of exceptions. - Thermal imagery shall be viewed on a monitor in the aircraft during the flight to ensure

that the subject solar panels have been inspected completely. - All FAA requirements must be met with regard to equipment installed on the aircraft, flight

safety, security, and noise. - Cost is usually higher than ground or elevation vantage point surveys

It is important to remember that surveys from any of the above vantage points have the same Required Site Conditions and follow the appropriate Standards.

Jersey Infrared Consultants provide Infrared Photovoltaic System Surveys from any of the above vantage points. Please contact us to discuss your specific project and which type of survey may best fit your needs.

What conditions are required for an Infrared Photovoltaic Survey?

- The success of an Infrared Photovoltaic System Survey is dependent on many conditions.

- No appreciable precipitation shall have fallen on solar panels during the hour prior to the

infrared inspection - At the time of the Survey, the surface of solar panels shall be free of dew, condensation,

ponded water, snow, ice, dirt, and debris - Winds in the area shall be less than 15 mph during the inspection

- Panels should be exposed to direct sunlite.

- The solar irradiance is at least 650 Watts/square meter across the face of panels during

the inspection

What safety requirements apply to Infrared Photovoltaic System Surveys?

Infrared Thermographers will need to be aware of and comply with numerous safety requirements. These may include OSHA and Site Specific Regulations, in addition to the National Fire Protection Association document, NFPA 70E.

Occupational Safety and Health Standards for General Industry 29 CFR, Part 1910 and Occupational Safety and Health Standards for Construction Industry 29 CFR, Part 1926 may apply to work with in the solar arrays.

Jersey Infrared Consultants has a full-time Safety Coordinator, and comprehensive Safety Compliance Program. All field personnel are equipped with the proper PPE equipment. For details or to discuss your facility’s specific concerns, please contact us.

What standards apply to Infrared Photovoltaic Surveys?

Standards that apply to Infrared Photovoltaic System Surveys are authored by the Occupational Safety and Health Administration, and Infraspection Institute. They cover topics including procedures, applications, certification of personnel, equipment use and performance standards, and safety. Following these standards will help ensure quality results from your Infrared Photovoltaic System Survey. A list of standards followed by Jersey Infrared Consultants can be found at Standards.

What should your report include?

Your report should be clear, easy-to-understand, and available in written and/or digital formats. The report will include the following sections:

• Introduction covers the procedures followed and provides information to assist understanding the report including priority assessment for problems.

• Thermographers Comments will discuss the areas surveyed, number of exceptions identified and special notation of any serious exceptions. This section should also include the manufacturer, model and serial number of the infrared imager, and the field-of-view of the infrared imager lens.

• Database provides a detailed list of all solar panels surveyed, including location, type of equipment, identification, status at the time of the survey, and notation

of exceptions along with their severity. Notations should be made of any panels not inspected.

• Exceptions should be documented with a Thermogram, control photograph with an indication of the exception, and a description that includes the following information:

- Equipment name and location

- Environmental conditions including air temperature, wind speed and direction, amount of solar irradiance, and the sky conditions

- Time the exception was documented

- Temperature rise over similar equipment (°C and/or °F)

- Detailed comments concerning the exception

When available, sketches or drawings of the solar field including the location(s) of any exceptions may be included.

Why should you use Jersey Infrared Consultants?

The high standards we set for service and reliability have earned us a reputation for excellence. All Infrared Photovoltaic System Surveys are performed by Infraspection Institute Certified Infrared Thermographers® using state-of-the-art equipment with direct traceability to the National Institute of Standards and Technology. All thermographers wear the appropriate PPE clothing.

Jersey Infrared Consultants’ safety compliance, background check, and drug screening programs are a part of our commitment to providing an unequaled level of client care and quality service. Our reports are clear, easy-to-understand, and comprehensive. They are delivered in a timely fashion in both written and electronic formats.

Our staff regularly conducts training classes, publishes technical articles, and participates in continuing education, enabling us to remain THE firm to hire for your Infrared Photovoltaic System Survey.