Flat Roofs

Infrared Flat Roof Moisture Surveys

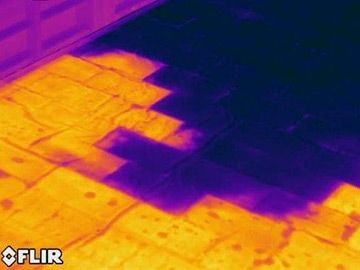

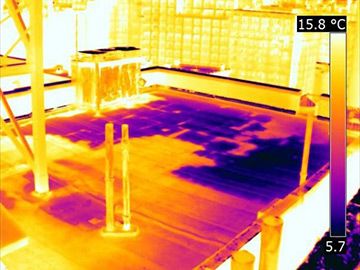

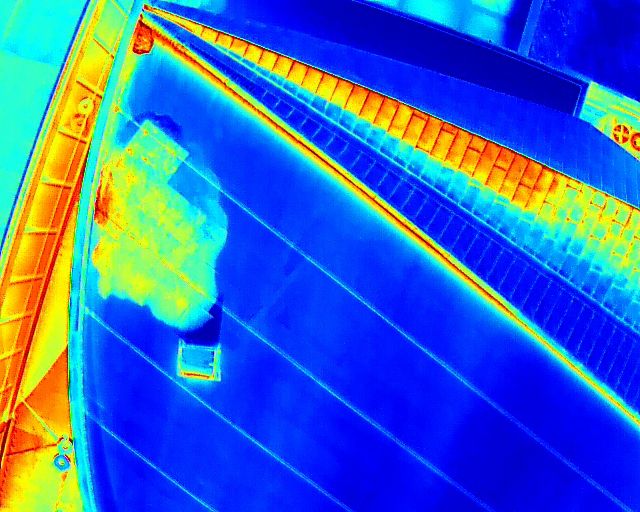

Infrared Flat Roof Moisture Surveys are used to detect and document latent moisture within a roofing system. The presence of moisture in a low slope roofing system causes changes in the thermal conductivity or thermal capacitance of the roof.

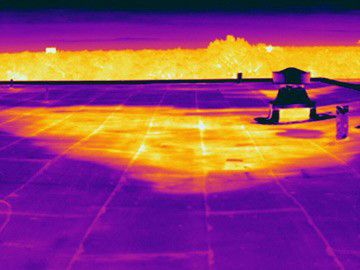

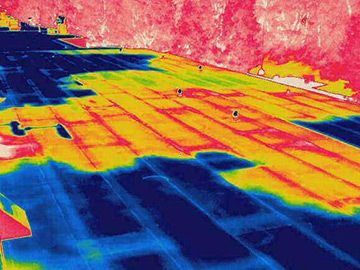

On a clear day, a roof surface is warmed by the Sun. While areas of the roof containing dry insulation resist solar loading, areas containing moisture readily absorb and retain heat. Following sunset, the roof surface begins to cool. Since wet insulation has a greater thermal capacity, those areas of the roof containing wet insulation cool off much more slowly than those areas of the roof containing dry insulation. By utilizing an infrared imager during post-sunset hours, areas of wet insulation are readily located based on their elevated temperature.

When an area of the roof with an elevated temperature is located during a walkover inspection, an invasive test is typically performed to verify the presence of moisture. This eliminates the possibility of false positive data as a result of variations in membrane materials, roof composition, or other environmental factors.

If moisture presence is confirmed, the perimeter of the moisture-damaged area is then outlined with spray paint on the roof surface. A thermogram is then recorded of the moisture-damaged area along with its size and location. Upon completion of the inspection, all imagery and associated data are incorporated into a comprehensive written report.

Condition Assessment

Quality Assurance

Insurance Claims

Aerial Inspections

If moisture presence is confirmed, the perimeter of the moisture-damaged area is then outlined with spray paint on the roof surface. A thermogram is then recorded of the moisture-damaged area along with its size and location. Upon completion of the inspection, all imagery and associated data are incorporated into a comprehensive written report.

Reports from an Infrared Flat Roof Moisture Survey provide useful information for many purposes including:

- Quality assurance of new or retrofitted roofs

- Condition assessment prior to warranty expiration

- Insurance claims to locate extent of storm damage

- Document roof condition prior to sale or lease of building

- Pre-bid documentation to help quantify the amount of roof to be replaced

- Provide documentation for legal cases

Aerial Inspections

Drone Aerial Inspection

See More

Jersey Infrared Consultants have been providing Infrared Flat Roof Moisture Surveys since 1984. All work is performed by Infraspection Institute Certified Infrared Thermographers® using state-of-the-art equipment. All work is performed in accordance with published standards and industry best practices.

Applications

- Condition Assessment

- Quality Assurance

- Preventive Maintenance

- Failure Investigation

- Legal Documentation

- Storm Damage Assessment

Benefits

- Survey 100% on the roof

- Most cost efficient method of testing

- Eliminate unnecessary replacement

- Identify problems when they are small

- Outline affected areas directly on the roof

Contact us to schedule your Flat Roof Moisture Survey.

FAQs

Infrared thermography is a form of non-contact, nondestructive testing used to detect and document thermal patterns associated latent moisture. Our high-resolution infrared imagers detect infrared energy emitted from the roof surface and convert it into an image which is displayed on a monitor screen.

During the day, the Sun heats the roof surface. Areas of the roof containing wet insulation will absorb and retain more heat than areas of the roof containing dry insulation. In the post-sunset hours, areas of the roof that contain moisture will show up as warm areas when viewed with a thermal imager.

When an area with an unusual thermal pattern is located, a moisture meter is typically used to confirm the presence of moisture. If moisture presence is confirmed, the perimeter of the area is outlined on the roof surface and a thermal image is recorded and incorporated along with other pertinent data into a written report.

Advantages of performing the survey from the roof surface include:

- Moisture probes can be performed at the time of the survey

- Affected areas can be outlined on the surface of the roof

- Small areas of moisture are detectable

- No flight pattern restrictions

- Cost is usually significantly less

- Survey very large areas (hundreds of thousands of SF) in a shorter period of time

- Look at areas that may not be accessible by foot due to site or safety issues

- Collect information to compare overall conditions of several different roofs

Jersey Infrared Consultants provide Infrared Flat Roof Moisture Surveys as well as Aerial Infrared Flat Roof Moisture Surveys. Please contact us to discuss your specific project and which type of survey may best fit your needs.

Since all IR imagers are NOT alike, it is imperative to use the appropriate thermal imager for the project. To perform an accurate Infrared Survey of a smooth-surfaced roof membrane (aluma-coated, TPO, PVC, EPDM) the Survey is best performed using a shortwave infrared imager. Using a long wave IR imager on such roof compositions may cause moisture damage to go undetected.

Due to physical properties, IRMA roofs, un-insulated roofs or roofs covered with ballast (river rock or rock larger than a walnut) are not good candidates for an Infrared Flat Roof Moisture Survey. Such systems are better suited for other test methodologies that we provide.

Please contact us to discuss your particular project.

Infrared thermography is based on the thermal properties of a roof system; nuclear testing measures the amount of hydrogen within the roofing system; and capacitance testing detects changes in electrical properties.

Please contact us to find out which test is best suited for your project.

The only conclusive test for moisture presence is to perform a minimally invasive test with a moisture meter. Current industry standards, including those published by ASTM and Infraspection Institute, require invasive testing to confirm the presence of wet and dry insulation.

Should you have questions or concerns regarding invasive testing, please call us.

Standards that apply to Infrared Flat Roof Moisture Surveys are published by the ASTM International (ASTM), the International Institute for Building Enclosure Consultants (IIBEC), and Infraspection Institute.

More information can be found on our Standards page.

Jersey Infrared Consultants reports are clear, easy-to-understand, and available in hardcopy and/or digital formats. Your report will include the following:

- Introduction covers the procedures followed and provides information to assist understanding the report

- Thermographer’s Comments will document the areas inspected; weather conditions prior to, and during the survey; overview of findings for each roof section, discussion, prognosis and recommendations.

- Roof Data Sheet provides a detailed description of the construction of the roof, conditions at the time of the Survey, the number of problem areas located, overall square footage of the problem areas, and the percentage moisture damage by roof section.

- Problem Areas are documented with a Thermogram and control photograph along with pertinent data for each

- Roof Drawing showing the size and location of problem areas along with the location of invasive test site where appropriate.